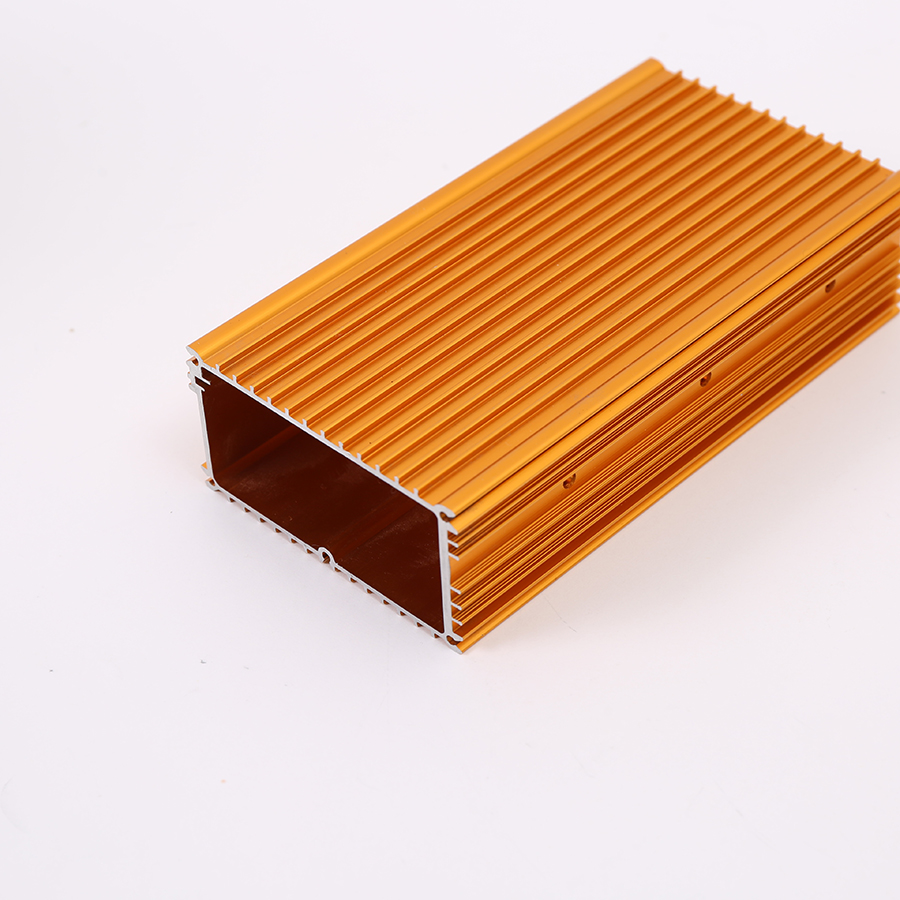

Square aluminum extrusion aluminium frame

The advantageous properties of aluminum alloys are light weight, good electrical and thermal conductivity, corrosion resistance, and good ductility. Aluminum alloys are soft and are often alloyed with copper, zinc, magnesium, silicon, manganese and lithium for added strength. Aluminum alloys are oxidized with an antioxidant film on the surface to prevent oxidation by air when the aluminum alloy is exposed to air.

Aluminum alloys are among the lightest metals available. Products are used in applications ranging from precision technology to everyday goods.

Product advantages

1. Welding technology suitable for industrial production of thin-walled aluminum tubes

2. The surface material can effectively prevent corrosion and largely extend the service life

3. Highly malleable, suitable for various working environments

Global Market

We are committed to developing international markets. Our customers come from all over the world, such as South Africa, Latin America, Europe, etc. Our high quality and low price products have won their recognition.

|

Application |

1. Lighting: solar reflective panels, LED light borders. |

|

Surface treatment |

Anodizing |

|

Color |

Silvery,light blue, dark blue,light golden,dark golden,champagne,black |

|

Deep process |

CNC, cutting,punching,drilling, milling, welding, bending, assembling |

|

MOQ |

300kgs for each mould |

|

Delivery time |

1.Sample 7 days |

|

2.Mass Production 30 days since sample is confirmed by Buyer. |

|

|

FOB Port |

SHANGHAI/QINGDAO/NINGBO |

|

payment terms |

T/T 30% deposit, balance before shipment |

|

settlement term |

pieces or weight |

|

Production capacity |

5000 tons per month, 60000 tons annually. |

|

Certificate and Standard |

ISO 9001:2015,ISO/TS 16949:2016 |

|

Quality Standard |

GB/T6892-2008,GB/T5237-2008 |