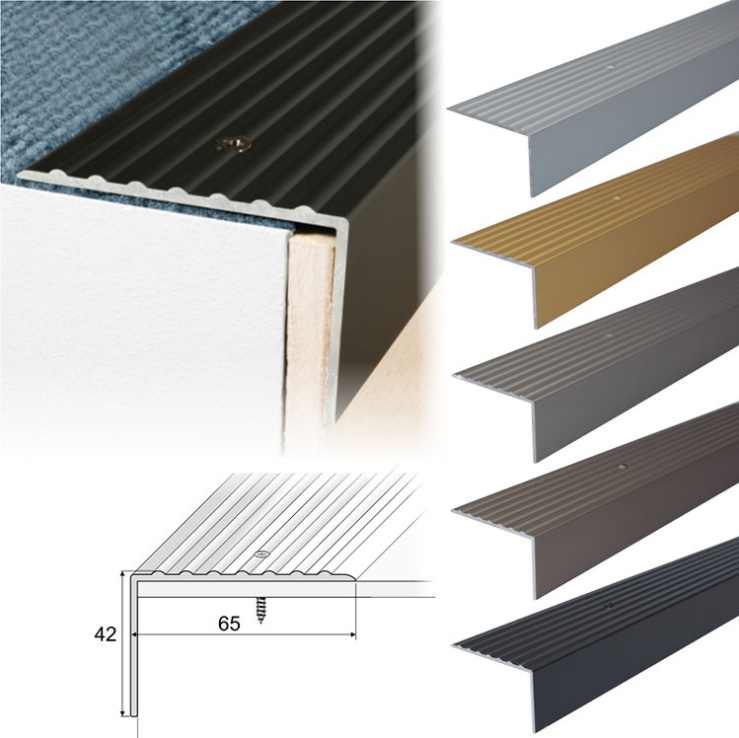

aluminum stair nosing anti-slip strip for stairs

| Product name: | aluminum stair nosing anti-slip strip for stairs |

| Place of Origin: | Jiangsu, China |

| Grade: | 6063 |

| Shape: | 7 shape |

| Surface Treatment: | Sandblasting |

| Hardness: | 15HW |

| Material: | Aluminum Alloy |

| Punching Hole | Square/ Round/ Triangle or custom |

| Al (Min): | 98.7% |

| Wall Thickness: | 0.6mm-2mm or custom |

| Length: | 8/ 10/ 12 mm |

| Color: | Silver/ Gold/ Black/ Champagne |

| Usage: | stair nosing |

| Brand Name: | xing yong lv Ye |

| Certificate: | ISO 9001:2015,ISO/TS 16949:2016 |

| Quality Standard | GB/T6892-2008,GB/T5237-2008 |

| PRICE TERM: | FOB CIF CFR CNF |

| Production Capacity | 1200 tons/Month |

Packaging Details

Top selling aluminum stair nosing anti-slip strip for stairs

A. Inside: packed with the plastic protective film or customized;

B.Outside: plastic shrink film for each bundle first, then waterproof Kraft paper for each box.

C.Carton:20 pieces per bundle, 80-200 per carton

Mold Workshop

Die and tooling are the most critical process for aluminum extrusion profile. Our die branch makes dies with state of computerized equipment, which ensures the die to be running properly fit to each individual extrusion press. We always work closely with our client to particular operational needs so completely that there is no big error in the process of making.

Extruding Line

Aluminum alloy surface is checked by quality man to make sure it is clean without any deformities. Dies must be tested and corrected to high precision.The alloys are extruded to aluminum profiles of various shapes which depending on the dies used.

Anodizing Line

Anodizing is a process to produce aluminum oxide coating on the profile's surface, so as to protect it form natural oxidizing, thus enhance its hardness and durability against different weather conditions.

Processing Machine

We have all been equipped with several dozens of world's most advanced production & processing facilities which are mainly imported from Germany,, Japan,Taiwan, etc. The ratio of new equipment is increasing year by year.The advanced production equipment are capable of handling most of request for complex and high precision processing of various types of aluminum extrusion profiles