OEM Custom Aluminum Extrusion Cnc Company Products - Aluminum column bracket for TV set – Xingyong

OEM Custom Aluminum Extrusion Cnc Company Products - Aluminum column bracket for TV set – Xingyong Detail:

| Product name: | Aluminum column bracket for TV set |

| Place of Origin: | Jiangsu, China |

| Material: | Aluminun Alloy |

| Alloy Temper: | 6063-T5 |

| Hardness: | ≥10HW |

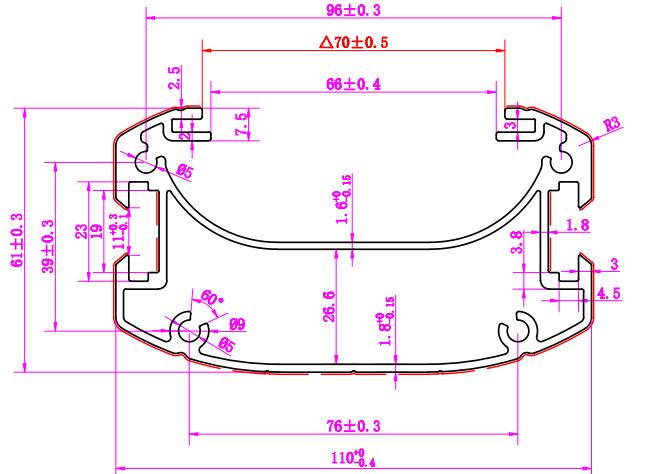

| Shape: | Custom |

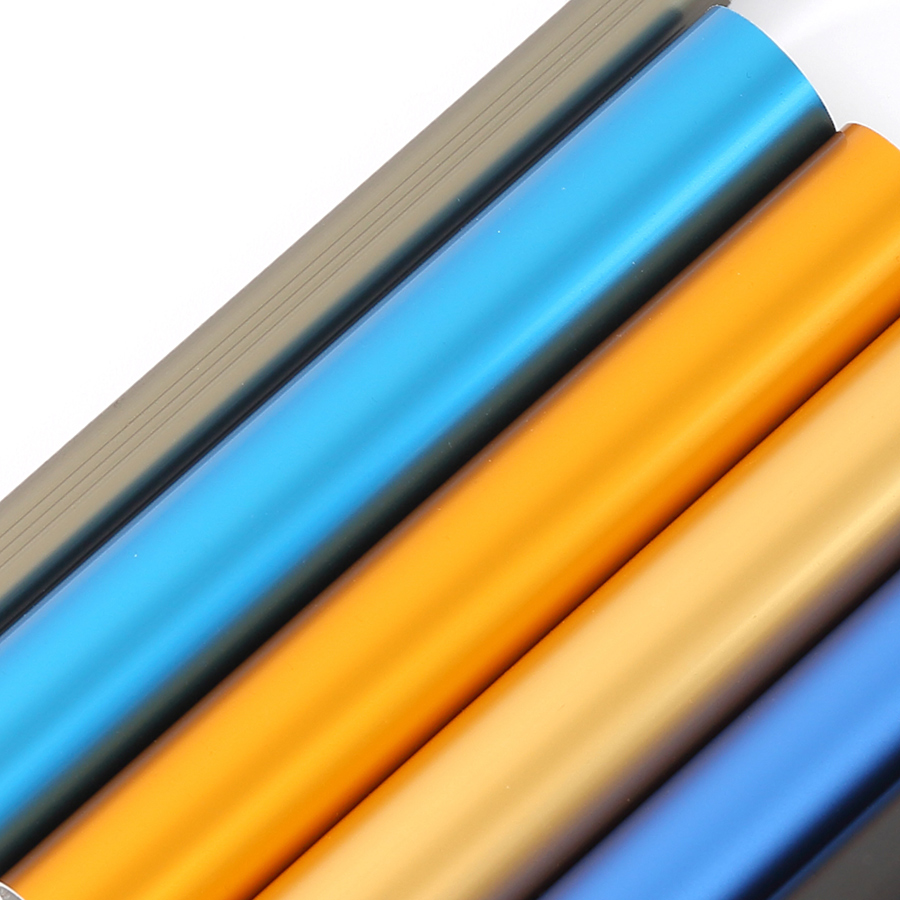

| Surface Treatment: | Acid-alkali sand anodizing |

| anodizing film | 6-12 um |

| Al (Min): | 98.7% |

| Outer Diameter | 110mm |

| Wall Thickness: | 1mm or custom |

| Length: | 600mm |

| Color: | Silver or custom |

| Application: | TV Bracket |

| Brand Name: | xing yong lv Ye |

| Certificate: | ISO 9001:2015,ISO/TS 16949:2016 |

| Quality Standard | GB/T6892-2008,GB/T5237-2008 |

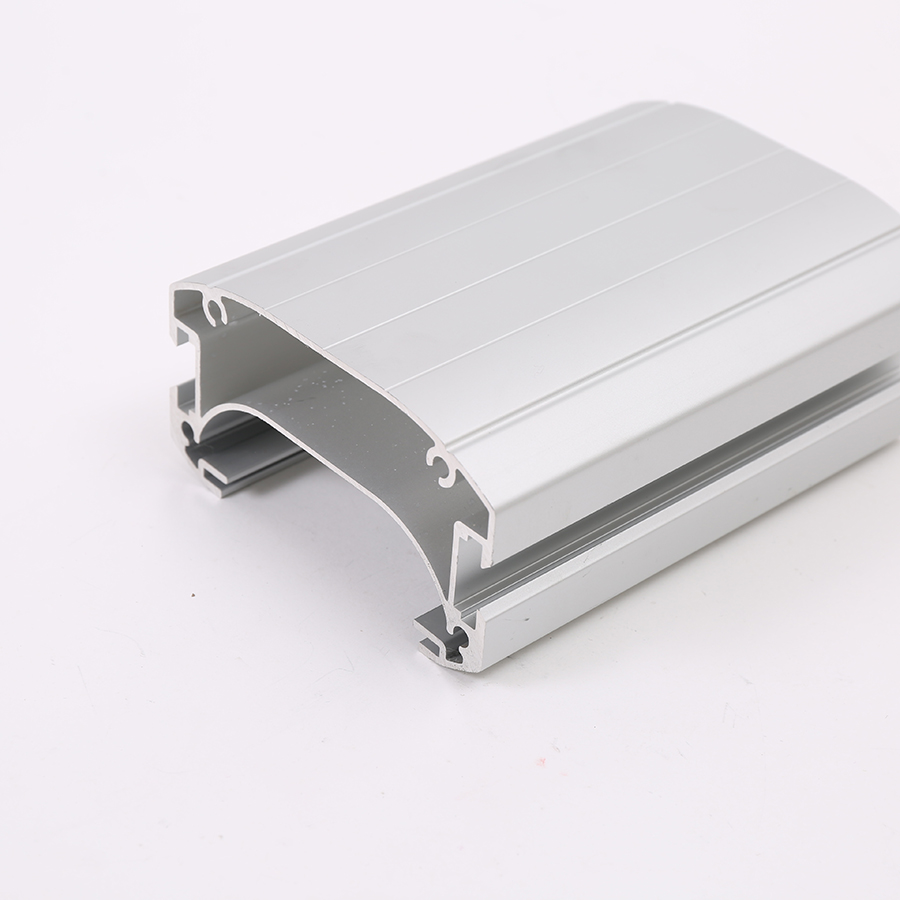

200 mm outer diameter aluminum bar will be put into the high temperature furnace, when temperature reach to 700 degrees, the aluminum bar will be very soft, it will be put into the aluminum extrusion machine, when the soft aluminum bar through passing through the mould,

The aluminum profile is ready.

The aluminum profile will be cut to around 6m length, and then loaded to large Transit frame.

After aluminum extrusion, the product will be moved to sand blasting line. there are four sandblasting machine, three machines make small sand and one machine make big sand.

The sand be hit into the aluminum profile, it will be hard to remove. The aluminum profile will be protected by the sand, and it will look frosted.

Next step is anodizing, the aluminum profile will be hang to the special shelf, and then put into the flowing five anodized pool, two before anodizing cleaning pool, one anodizing pool, two after anodizing cleaning pool. After anodized, the aluminum profile will be dried by natural air, until there is no water on the surface and inside.

When the profile dried enough, it will be packaged to protect the surface, then be transferred to deep processing department, it will be cut, pushed,drilled or welding, then be well packaged in carton or tray.

Product detail pictures:

Related Product Guide:

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for OEM Custom Aluminum Extrusion Cnc Company Products - Aluminum column bracket for TV set – Xingyong , The product will supply to all over the world, such as: Saudi Arabia, Morocco, Albania, We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.